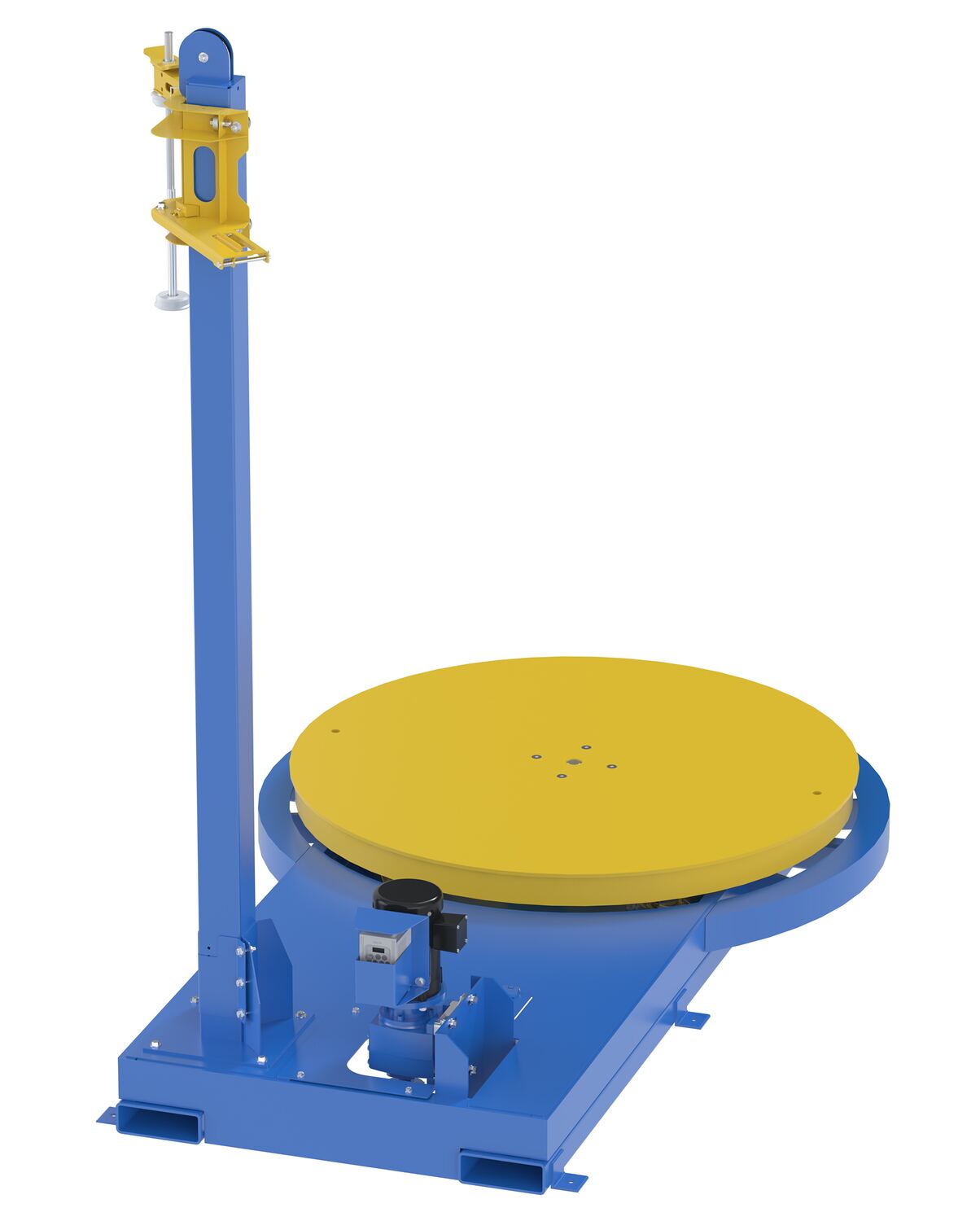

Professional Tips to Make Certain Effective Stretch Wrap Machine Repair Service Practices

When it concerns extend wrap equipment repair services, recognizing the typical concerns that can emerge is important. You'll desire to be geared up with the right devices and a clear troubleshooting procedure to deal with troubles successfully. Regular upkeep can't be neglected either, as it plays an essential function in avoiding bigger concerns down the line. Allow's explore these key locations to assure your repair work techniques are as effective as possible.

Recognizing Usual Stretch Cover Equipment Issues

When you make use of a stretch cover device regularly, it's crucial to recognize common concerns that can arise. One frequent issue is inconsistent tension in the film, which can bring about loosened or excessively tight wraps. You'll wish to examine the stress setups consistently to confirm they're calibrated appropriately. Another usual concern is movie sticking or tearing, usually brought on by incorrect loading or worn-out components. If you notice this, examine the movie path and change any damaged components. Furthermore, look for error messages or uncommon noises during operation; these can indicate mechanical breakdowns. Obstructing is one more frustration, generally stemming from debris or misaligned rollers. Routinely clean the maker and validate all components are straightened to avoid this. By remaining in advance of these issues, you can keep your stretch cover equipment running efficiently and efficiently, decreasing downtime and maintaining performance in your procedures.

Crucial Tools for Efficient Repair Services

To efficiently repair a stretch wrap machine, having the right devices on hand is essential. These will certainly help you take on most mechanical problems.

Do not neglect safety and security equipment, such as gloves and safety goggles, to safeguard on your own while working. An excellent flashlight is necessary, too, as it assists illuminate limited areas where you could need to inspect components.

In addition, maintain a toolkit with spare parts like belts, rollers, and integrates. These can save you time throughout repair work, allowing you to replace damaged parts on the place. A service handbook particular to your device will give support and schematics, making repairs much more straightforward. With these essential tools, you'll be fully equipped to deal with any type of repair challenge that comes your method.

Step-by-Step Troubleshooting Guide

When repairing your stretch cover machine, it's vital to begin with a review of usual issues you may deal with. By utilizing the ideal diagnostic devices, you can quickly identify the origin of the trouble. Allow's go through a detailed guide to obtain your machine back up and running successfully.

Usual Problems Introduction

While stretch wrap devices are vital for efficient product packaging, they can run into a variety of concerns that interfere with procedures. One common trouble is inconsistent film stress, which might lead to loose or excessively limited wraps. If you notice this, inspect the stress setups and make certain the film is filled appropriately. One more concern is movie tearing during the wrapping process; this usually stems from boring reducing blades or improper film placement. Frequently examine and change blades as required. In addition, if the equipment will not begin, confirm that all safety buttons are involved and the power supply is functioning. Lastly, look out for unusual sounds, which can show mechanical wear that demands immediate focus. Addressing these concerns promptly can conserve you time and sources.

Diagnostic Tools Use

Reliable repairing begins with the appropriate diagnostic tools available. Begin by collecting crucial devices like multimeters, thermal cams, and pressure evaluates. stretch wrap machine repair. Each tool serves a certain function in determining issues

First, make use of a multimeter to examine electric connections and assurance power moves properly. Next off, utilize a thermal camera to discover overheating elements, which can indicate failures. Then, use a pressure gauge to keep an eye on pneumatically-driven systems for leaks or disparities.

As you test, document your findings. This document assists track recurring issues and improve future repair work. Ultimately, do not wait to consult your equipment's handbook for certain troubleshooting actions related to the version. With these tools and a systematic strategy, you'll effectively identify and solve machine concerns.

The Relevance of Normal Maintenance

Regular upkeep is essential for keeping your stretch wrap device running efficiently and effectively. By organizing preventative upkeep, you can catch prospective issues before they intensify, saving you money and time. Remaining on top of maintenance periods warranties your devices stays in top form and reduces unexpected downtime.

Preventative Maintenance Conveniences

When you focus on preventative maintenance for your stretch cover click maker, you not just extend its life-span but also improve its performance. Routine checks assist determine prospective issues prior to they rise into costly fixings. By keeping elements tidy and oiled, you assure smoother operation, which can cause better wrapping top quality and lowered material waste.

In addition, a properly maintained device operates with fewer disturbances, decreasing downtime in your production line. You'll likewise discover that routine maintenance can increase employee spirits, as they can rely upon tools that executes regularly. Ultimately, staying aggressive with upkeep can enhance your overall roi, permitting useful reference you to allot sources better. Accept preventative maintenance, and watch your procedures grow.

Arranged Maintenance Intervals

Although it may be alluring to miss maintenance checks, sticking to set up upkeep intervals is vital for keeping your stretch wrap maker running smoothly. Normal upkeep aids you identify potential problems prior to they rise into costly fixings. By sticking to an established routine, you guarantee that all vital components receive the attention they require, protecting against unexpected failures and downtime.

Make it a habit to log upkeep activities and track performance patterns. This data can direct future maintenance and assist you adjust your procedures. Do not fail to remember to consult your maker's manual for specific suggestions pertaining to maintenance periods. Investing time in arranged upkeep not only prolongs your machine's life-span yet additionally improves performance in your procedures. Keep positive, and your stretch wrap equipment will thank you!

Safety And Security Protocols During Repair

Prior to beginning any kind of job, confirm the equipment is powered down and secured out to protect against unintended startups. Familiarize on your own with the equipment's technological paperwork and safety and security cautions; this knowledge can avoid unsafe mistakes.

Training and Ability Development for Technicians

Reliable training and ability growth for service technicians are important in guaranteeing effective stretch wrap machine repairs. You require a solid understanding of the machine's parts and just how they work together.

Encourage continual education and learning by going to workshops and seminars concentrated on the current innovations and repair check my reference work techniques. This maintains you updated on industry patterns and aids you embrace ideal techniques. Combining skilled technicians with novices promotes a learning atmosphere where skills can be shared and developed.

Lastly, execute a mentorship program to lead less experienced service technicians, ensuring they obtain the self-confidence and competence needed for efficient repairs. Buying training and ability advancement not just improves repair work top quality however additionally increases the total efficiency of your operations.

When to Seek Expert Aid

Understanding when to look for professional assistance can conserve you time and avoid more damage to your stretch cover machine. If you observe relentless issues like uncommon noises, inconsistent covering, or mistake messages that you can't fix, it's finest to hire a professional. Don't disregard small troubles, as they can escalate into expensive fixings if left unaddressed.

Additionally, if you've currently tried repairs but haven't seen enhancement, it's a clear indicator that specialist treatment is required. Dealing with complicated systems without the appropriate knowledge can cause even more considerable failures.

Often Asked Concerns

Just How Usually Should Stretch Cover Machines Be Serviced?

You need to service stretch wrap machines every six to twelve months, depending upon usage. stretch wrap machine repair. Routine maintenance avoids break downs, improves performance, and extends the device's life expectancy, ensuring you get the most out of your investment

What Are the Indicators of a Stopping Working Stretch Cover Maker?

You'll notice a stretch cover maker is falling short if it generates inconsistent wraps, makes uncommon sounds, or reveals mistake messages. Furthermore, frequent jams or slow-moving operation can show underlying issues needing prompt interest and repair.

Can I Fix My Device Without Previous Experience?

You can attempt to fix your maker without prior experience, yet it's dangerous (stretch wrap machine repair). You might deal with challenges recognizing components or diagnosing issues. Take into consideration seeking advice or expert aid to prevent more damage and warranty efficient fixings

What Is the Typical Life-span of a Stretch Wrap Maker?

The standard life expectancy of a stretch cover machine is usually around 5 to one decade, depending on use and upkeep. Regular upkeep can expand its life, guaranteeing you get the most out of your financial investment.

Are There Specific Brands Understood for Better Reliability?

Yes, some brand names like Aetna and Lantech are recognized for their integrity. You'll locate that buying well-reviewed machines typically causes less upkeep concerns and longer life-span, conserving you time and prices in the future.

Conclusion

By prioritizing upkeep, making use of the right devices, and following a systematic troubleshooting guide, you can boost your stretch cover equipment fixing techniques. Bear in mind, normal examinations and documents aid capture problems early, while adhering to safety and security methods maintains you and your group risk-free. Purchasing training and fostering a collaborative setting will certainly additionally improve your abilities and effectiveness. Do not wait to look for specialist assistance when needed-- it's all concerning making sure peak efficiency and durability of your equipment.